product introduce:VSF Series: Multi-la

VSF Series: Multi-layer stainless steel filter screen integrates filter elements inside. When differential pressure reaches the preset pressure after filtration, the liquid in the filter is discharged and the filter cake is removed by vibrator, then filter elements are cleaned for the filtration next time. VSF Filter has the outstanding following features: wide application, close operation, multi-function, large filter area, high dirt holding capacity, easy to backblow the filter cake off and automatic running. Usually VSF filter system runs continuously by consisting two filters (one filtering and the other one standby) and has PLC control system, which can automatically carry out precoating, filtering, discharging, cleaning and other procedures. More VSF Filter unit can be integrated into a larger filter system. Applicable industries: Petro-chemical, beverage, fine chemicals, oil, water treatment, titanium dioxide etc.

Main Specification

■ Housing Diameter(mm): 300-2400

■ Filtration rating (μm): 0.5-600

■ Filter Area (m2): 2-90

■ Housing Material: 304,316L,CS

■ Applicable Viscosity (cp): 1-2000

■ Temperature (℃): 200

■ Design pressure (MPa): 0.6,1.0

■ Jacket: An external metal jacket placed over the filter housing and filled with hot oil (0.2MPa) or water (0.4MPa) to maintain product temperature

Type

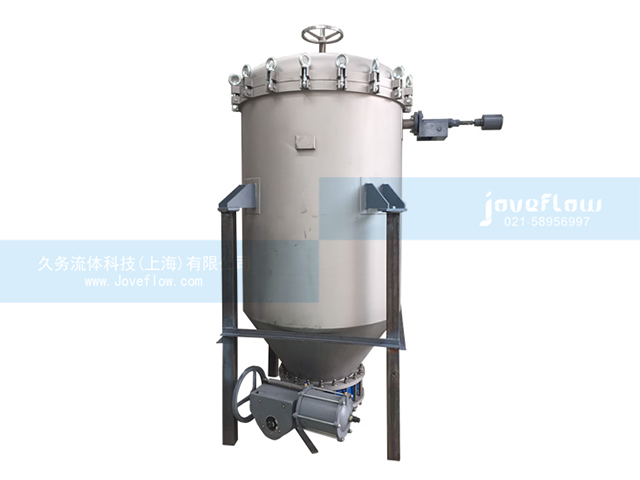

Upper vibration

The vibrator is located on the upper part of the filter elements.

Central vibration

The vibrator is located in the middle of filter elements.

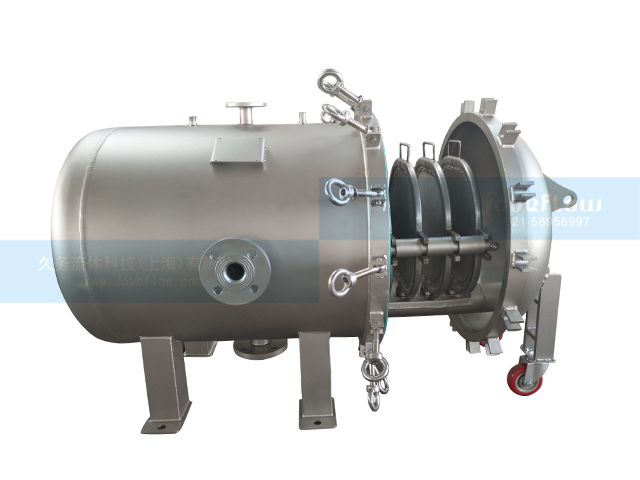

Horizontal Leaf Filter

Pls check more technical datas as below :

|

Model |

Filter area(m2) |

Cake volume (L) |

Capacity (T/h) |

Working Pressure( Mpa ) |

Working Temperature (℃) |

Filter Tank Volume(L) |

Weight(kg) |

|||

|

Oil |

Resin |

Drink |

Rated pressure |

Max pressure |

||||||

|

VSF-2 |

2 |

30 |

0.4-0.6 |

1-1.5 |

1-3 |

0.1-0.4 |

0.5 |

≤150 |

120 |

300 |

|

VSF-4 |

4 |

60 |

0.5-1.2 |

2-3 |

2-5 |

250 |

400 |

|||

|

VSF-7 |

7 |

105 |

0.5-1.8 |

3-6 |

4-7 |

420 |

600 |

|||

|

VSF-10 |

10 |

150 |

1.0-3 |

5-8 |

6-9 |

800 |

900 |

|||

|

VSF-12 |

12 |

240 |

1-4 |

6-9 |

8-11 |

1000 |

1100 |

|||

|

VSF-15 |

15 |

300 |

1.5-5 |

7-12 |

10-13 |

1300 |

1300 |

|||

|

VSF-20 |

20 |

400 |

2.5-6 |

9-15 |

12-17 |

1680 |

1700 |

|||

|

VSF-25 |

25 |

500 |

3-7 |

12-19 |

16-21 |

1900 |

2000 |

|||

|

VSF-30 |

30 |

600 |

4-8 |

14-23 |

19-25 |

2300 |

2500 |

|||

|

VSF-36 |

36 |

720 |

4.5-9 |

16-27 |

23-31 |

2650 |

3000 |

|||

|

VSF-45 |

45 |

900 |

5.5-11 |

21-34 |

30-38 |

3200 |

3500 |

|||

|

VSF-52 |

52 |

1040 |

6.5-13 |

24-39 |

36-44 |

3800 |

4000 |

|||

|

VSF-60 |

60 |

1200 |

7.5-15 |

27-45 |

42-51 |

4500 |

4500 |

|||

|

VSF-70 |

70 |

1400 |

8.5-15 |

30-52 |

48-60 |

5800 |

5500 |

|||

|

VSF-80 |

80 |

1600 |

9.5-18 |

36-60 |

56-68 |

5860 |

6000 |

|||

|

VSF-90 |

90 |

1800 |

10.5-21 |

40-68 |

64-78 |

6700 |

6500 |

|||

Leaf Filter Overall and Installing Dimensions

|

Model |

Tank Diameter |

Filter spacing |

Inlet |

Outlet |

Overflow Port |

Discharge Port |

Height |

|

VSF-2 |

Ø400 |

50 |

DN25 |

Ø32 |

DN25 |

Ø50 |

1200 |

|

VSF-4 |

Ø500 |

50 |

DN40 |

Ø45 |

DN25 |

Ø50 |

1750 |

|

VSF-7 |

Ø600 |

50 |

DN40 |

Ø45 |

DN25 |

Ø50 |

1850 |

|

VSF-10 |

Ø800 |

70 |

DN50 |

Ø57 |

DN25 |

Ø300 |

2500 |

|

VSF-12 |

Ø900 |

70 |

DN50 |

Ø57 |

DN40 |

Ø400 |

2550 |

|

VSF-15 |

Ø1000 |

70 |

DN50 |

Ø57 |

DN40 |

Ø500 |

2580 |

|

VSF-20 |

Ø1000 |

70 |

DN50 |

Ø57 |

DN40 |

Ø500 |

2800 |

|

VSF-25 |

Ø1100 |

70 |

DN50 |

Ø57 |

DN40 |

Ø500 |

2950 |

|

VSF-30 |

Ø1200 |

70 |

DN50 |

Ø57 |

DN40 |

Ø600 |

3000 |

|

VSF-36 |

Ø1200 |

70 |

DN65 |

Ø76 |

DN50 |

Ø600 |

3500 |

|

VSF-45 |

Ø1300 |

70 |

DN65 |

Ø76 |

DN50 |

Ø600 |

3600 |

|

VSF-52 |

Ø1400 |

75 |

DN80 |

Ø80 |

DN50 |

Ø600 |

3700 |

|

VSF-60 |

Ø1500 |

75 |

DN80 |

Ø80 |

DN50 |

Ø600 |

3800 |

|

VSF-70 |

Ø1600 |

80 |

DN80 |

Ø80 |

DN50 |

Ø700 |

3900 |

|

VSF-80 |

Ø1700 |

80 |

DN80 |

Ø80 |

DN50 |

Ø700 |

3900 |

|

VSF-90 |

Ø1800 |

80 |

DN80 |

Ø80 |

DN50 |

Ø700 |

4000 |

Main Use and Application of Pressure Leaf Filter

The vertical leaf filter is widly used for many industry such as:

1. Oil industry: hair-pressing machine oil filter oil filter decolorization hydrogenated oil filters oil filters such as winter.

2. Food industry: sugar glucose such as the sugar solution activated carbon filter decolorization wine fruit juice soft drinks and so on to clarify the filter.

3. Chemical industry: petrochemical industry inorganic chemicals organic chemicals in the process of the crystals separated from the catalyst for a variety of filtering separation chemical products such as decolorization filter.

4. Environmental protection industry: rivers lakes water sewage treatment station supernatant insurance purification filter water purification filter back to the swimming pool.

400 Phone:{dede:global.cfg_tel/}

Tel:+86.021.58956997

FAX:+86.021.58956997

TEL:17301638937

QQ:103735833

Email:sales@joveflow.com

Address:上海市沪松公路1658号

Welcome to consult us!