product introduce:Multiple wedge filter elements are integrated. In case of blockage the filter elements can be backwashed group by group with the unique backwash arm.

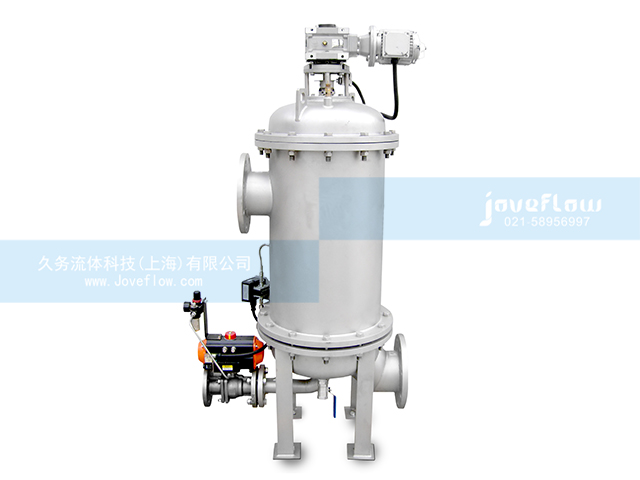

Backwash Self-cleaning Filter is a new generation of backwash filter systems designed and developed independently. Multiple wedge filter elements are integrated. In case of blockage, the filter elements can be backwashed group by group with the unique backwash arm. Filter elements are cleaned automatically by means of differential pressure control and timing control. When the differential pressure of the outlet increases to the set value due to accumulation of impurities on the filter element surfaces, or the timer reaches the preset time, the electric control box sends the signal to drive the backwash mechanism. When the backwash sucker port is aligned with the filter element inlet, the drain valve is opened, and water is drained to relieve pressure. A negative pressure zone with the relative pressure lower than the water pressure outside the filter elements appears on the inner sides of the sucker and filter elements, part of circulating clean water is forced to flow into the filter elements from outside the filter elements, and impurities on the inner walls of filter elements are reversely backwashed into the tray and discharged through the drain valve. With the special screen, injection effects can be produced in filter elements, and all impurities can be flushed away from the smooth inner walls. When the differential pressure of the inlet and outlet of the filter is normal or the set time of the timer ends, the motor stops running, and the electric drain valve is closed. In the whole process, the material flows continuously, a little water is needed for backwashing, and continuous and automatic production (controlled by PLC or DCS) is realized.

Type

BSF-V

Suitable for small flow or fine filtration conditions.

BSF-H

Suitable for medium flow or coarse precision filtration.

BSF-M

Suitable for coarse precision and super large flow filtration.

How it works

[ Filtering ] Liquid flows into the filter via the inlet, part of liquid flows directly through filter elements from the lower ends; another part of liquid flows through the distribution pipe and into the upper part of the filter and then flows into the filter elements from the upper and lower ends at the same time,and then flows through the internal surface of filter element and goes out from the outlet. Impurities are intercepted by the elements and the filter cake slowly accumulates, which leads to gradually pressure drop increasing between the inlet and outlet. It indicates that the filter cake reaches certain thickness,and the flux of filter element becomes lower.

[ Back-flushing ] When the preset pressure drop or time exceeds, the self-cleaning program is triggered. The gear motor drives the cleaning arm to aim at one element to partly cap the upper end of the element and connect its lower end to the cleaning nozzle. And then the cleaning valve opens and connect the element and discharging pipe. the differential pressure between the element’s outside and discharging nozzle will make the filtrate back-flush the filter element, filter cake dislodged and be purged downward into the sewage pipe. After one element cleaned, the cleaning valve closes and the cleaning arm aims at the next one. When all filter elements cleaned, the entire back-flushing sequences are completed.

[ Positioning ] Positioning disc and cleaning arm are installed on the shaft driven by the gear motor. Each positioning hole on the disc matches each element and cleaning arm are corresponding to one hole. When one hole reaches the channel of positioning sensor, the sensor output the signal to stop the gear motor. The cleaning arm has aimed at one element at the same time. The cleaning valve opens for several seconds till the element is cleaned. Then the gear motor continues rotating. When the next hole on disc reaches the sensor channel, the gear motor will stop and the next element is cleaned.

Main Specification

■ Micron Rating: 50-1500μm

■ Maximum Operating Pressure: 1.0MPa/1.6MPa

■ Flow Rate Range: 5 ~8500m3/h

■ Housing Material: SUS316L/SUS304

■ Element Material: SUS316L/SUS304

■ Sealing Material: NBR/FKM/Silicone/PTFE/EPDM

■ Jacket: An external metal jacket placed over the filter housing and filled with hot oil (0.2MPa) or water (0.4MPa) to maintain product temperature

■ Explosion Proof: Explosive-proof components are used for flammable and explosive operating conditions

■ Multi-filter group: Multiple filters combined in parallel to meet higher flow rate requirement.

Technical Characteristics and Advantages

■ Automatic continuous online filtration and continuous flow in backwashing, reducing the downtime and maintenance costs.

■ Large filtering area, low surface flow, small pressure loss and energy consumption, fine filtration, low backwash frequency and conservation of backwash water.

■ High-performance filter elements, accurate filter gaps, high-efficiency backwash, high-strength structure and long service life (more than 10 years).

■ Pulse backwash with high strength, good effects, short duration and low water consumption. The drain valve is opened when filter elements are aligned.

■ Water is filled into both ends of filter elements at the same time, increasing the flow. Free water flow can help to reduce surface blockage and avoid blockage of one end of the filter element.

■ The structure is compact. Large-flow filtration can be realized with one filter. The installation space and construction costs can be saved significantly.

■ High degree of integration, no need for a large number of automatic valves, connectors or seals, high reliability and low costs of operation and maintenance.

■ The automatic control system has high reliability, and the interface is intuitive and easy to operate. The filters can be controlled to work efficiently according to the actual conditions.

■ Applicable industry: water treatment paper making iron and steel making mining petrochemical machining municipal utilities agricultural irrigation etc. ■ Applicable liquid: groundwater seawater lake water reservoir water circulating cooling water chilled water high/low-pressure water spray point injection water heat exchange water sealing water bearing cooling water oil well injection wall process circulating water machining coolant cleaning agent cleaning water etc. ■ Main filtration effects: removal of large particles water purification and protection of key parts. ■ Filtration type: backwash filtration and automatic continuous online filtration.

400 Phone:{dede:global.cfg_tel/}

Tel:+86.021.58956997

FAX:+86.021.58956997

TEL:17301638937

QQ:103735833

Email:sales@joveflow.com

Address:上海市沪松公路1658号

Welcome to consult us!